JINLANG - Foaming Agent

Fujian Jinlang New Material Technology Co., Ltd was established in March 2005 and is located in Jinjiang City, Fujian Province. The company products and sales of rubber and plastic additives, with foaming agents and other functional additives as its core products.

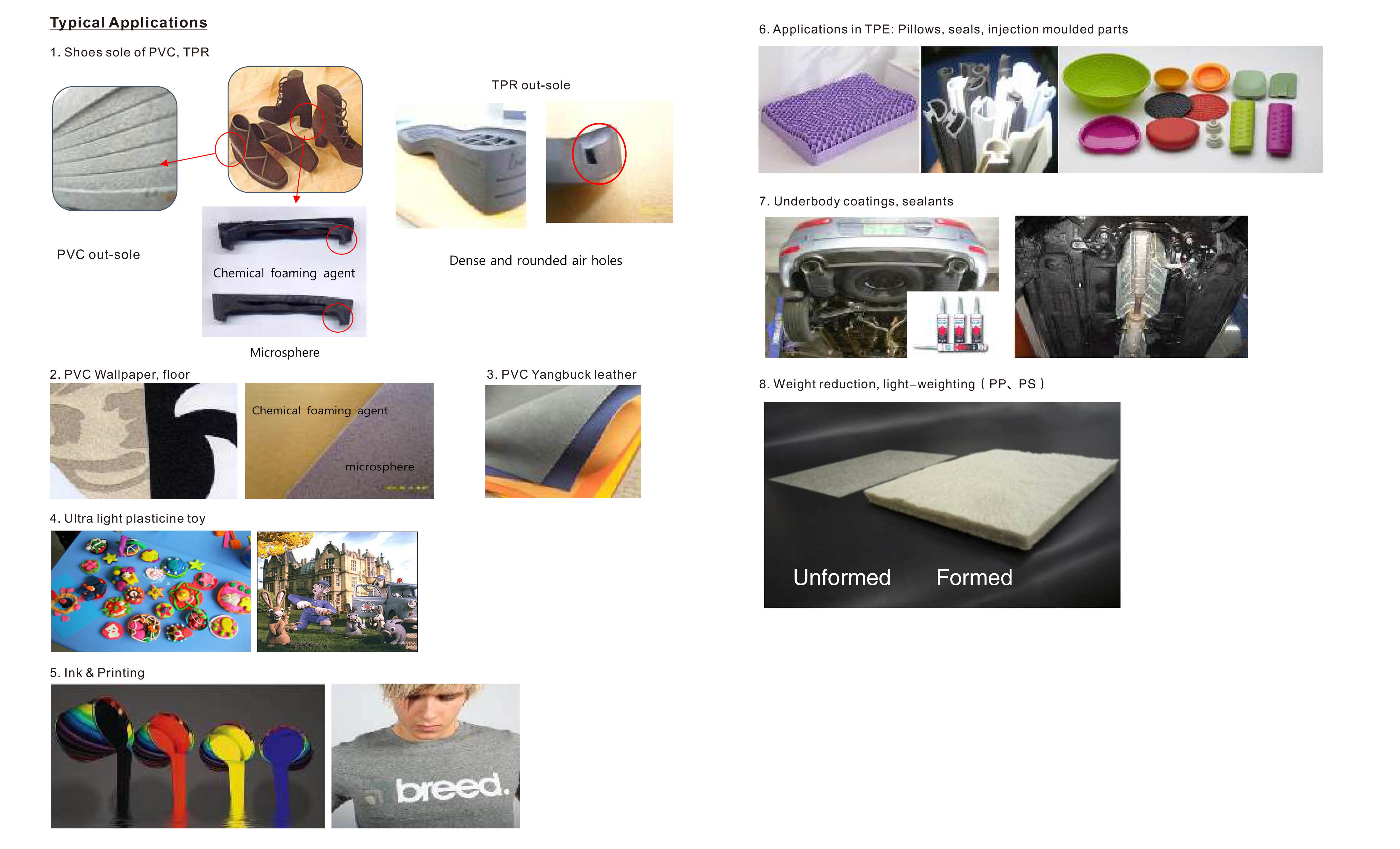

R&D personnel of JINLANG Company had assimilated the excellents production and application technology of the foaming agents both at home and abroad, and based on this, they had successfully developed more excellent performance and competitive modified foaming agents. These series of foaming agents are widely used in the injection technology of EVA MD, EVA slippers, PVC soft and hard foamed products, TPR, rubbers, PE, PS, NBR+PVC copolymer and other various engineering foamed products.

PRODUCT CATALOG

| Product Name | Grade | Dec.Tem. | Gas Volume | Particle Size | Applications |

| ℃ | ml/g(STP) | μm | |||

| High Temperature Foaming Agent | AC1000 | 203±3 | ≥220 | 12-14 | Various plastics and rubber |

| AC3000 | 202±3 | ≥220 | 6-8 | ||

| AC7000 | 200±3 | ≥220 | 3-5 | ||

| Medium Temperature Foaming Agent | JL-M | 155±5 | 180±5 | 6-8 | Various plastics and rubber, EVA MD mold |

| Low Temperature Foaming Agent | ACP-H | 130±5 | 140±5 | 7-10 | Various plastics and rubber, EVA MD mold. With Formaldehyde |

| AC-L | 152±5 | 160±5 | 6-8 | Environment-friendly rubber low temperature foaming agent | |

| EVA Injection Foaming Agent | AC6000H | 180±5 | 185-195 | 6-8 | EVA injection technology |

| PVC Artificial Leather Foaming Agent | AC3000F | 200±2 | ≥220 | 6-8 | PVC and semi-PU artificial leather |

| AC180F | 145±5 | 175±5 | 6-8 | ||

| Environment-friendly Endothermic Foaming Agent | N1000 | 160±5 | 125±5 | 10-12 | PVC, TPR, PS extrusion and injection foaming process |

| N2000 | 160±5 | 110±5 | 8-10 | ||

| N3000 | 160±5 | 100±5 | 6-8 | ||

| Endothermic-Exothermic Balanced Blowing Agent | AC232 | 170-185 | 160±10 | 8-10 | PVC, TPR, PS extrusion and injection foaming process |

| AC234 | 170-185 | 190±10 | 8-10 | ||

| AT4000 | 170±5 | 190±5 | 8-10 | ||

| Transparent White Foaming Agent | CAP | 130±5 | 135±5 | 8-12 | Coarsse hole foaming |

| 130 | 130±5 | 135±5 | 8-12 | Fine cell foaming | |

| Masterbatch Foaming Agent | PH50 | 203±2 | 112±2 | 13-15 | Environmentally friendly particulate blowing agent |

| EH50 | 180±5 | 110 | 13-15 | ||

| EM50 | 150±5 | 80 | 13-15 |

General Notes

1) The microcells should be stored away from direct sunlight, well-ventilated under 40°C. The expensive property may reduce, if it stays at high temperature areas for long time.

2) Thoroughly mix the microcells and resin and maintain temperature under 60°C.

3) Need to wear safety glasses, protective gloves ect.

4) If eye contact, rinse thoroughly with plenty of water. Skin contact, wash off with plenty of water. If ingestion, induce vomiting and wash with plenty of water, then call a physician or poison Control Center immediately