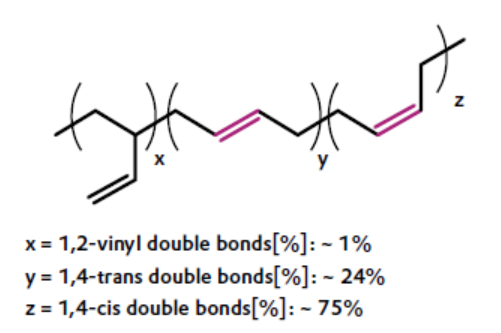

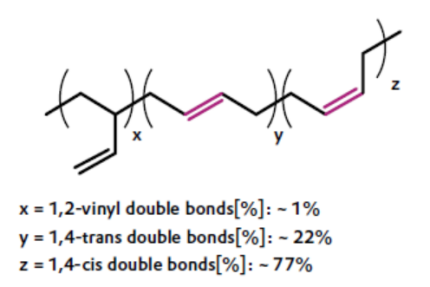

Based on their characteristic microstructure, all POLYVEST® grades exhibit an excellent reactivity and can be used for a broad variety of applications. The unsaturated polymer backbone of all POLYVEST® grades offers the opportunity for various crosslinking options, like sulfur curing and oxidative drying. In addition, the functional moieties of POLYVEST® HT and POLYVEST® MA provide further options for crosslinking and make polymer modification feasible. Due to its rubberbased nature, POLYVEST® ST is perfectly suited as a reactive plasticizer in tire and mechanical rubber goods applications.

BENEFITS AT A GLANCE

- Low viscosity

- Excellent chemical resistance to acids and bases

- High water resistance

- Excellent electrical insulation properties

- Low temperature flexibility

- Low moisture and oxygen permeability

POLYVEST® PRODUCT RANGE

POLYVEST® 110 - non-functionalized liquid polybutadienes

POLYVEST® 130- non-functionalized liquid polybutadienes

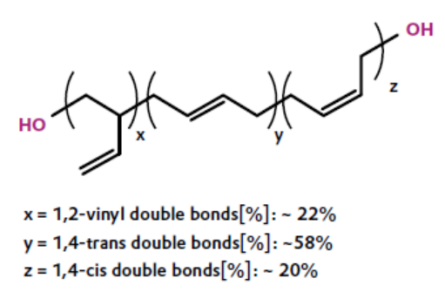

POLYVEST® HT- hydroxyl-terminated liquid polybutadiene

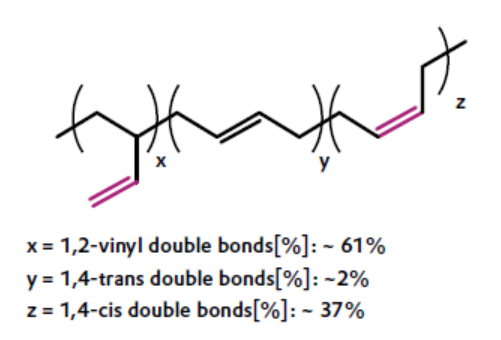

POLYVEST® MV - mid vinyl content, non-functionalized liquid polybutadiene

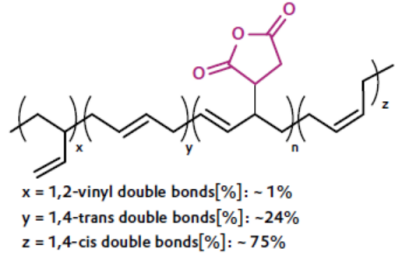

POLYVEST® MA75 - maleic anhydride-functionalized liquid polybutadienes

POLYVEST® ST- silane-terminated liquid polybutadiene

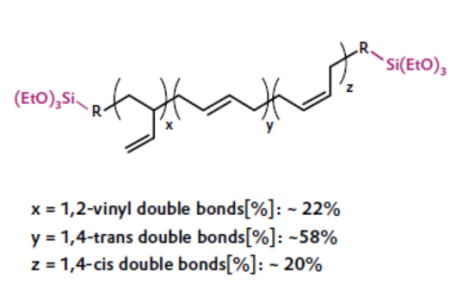

POLYVEST® EP MAT- methacrylate-terminated liquid polybutadiene

|

Product Range |

||||||||

|

POLYVEST® |

110 |

130 |

EP* MV |

MA 75 |

EP* MA 100 |

HT |

ST-E 60 |

EP* MAT |

|

Specifications |

|

|

|

|

|

|

|

|

|

Viscosity at 20°C [mPa s] |

700-860 |

2,700-3,300 |

5,000- 7,000 |

6,000-9,000 |

- |

- |

7,500-15,000 |

6,000-9,000 |

|

Viscosity at 30°C [mPa s] |

- |

- |

- |

- |

10,000-16,000 |

4,000-5,500 |

|

- |

|

Acid Number [mg KOH/g] |

≤0.3 |

≤0.3 |

≤0.5 |

70-90 |

95-115 |

- |

|

- |

|

Hydroxyl Number [mg KOH/g] |

- |

- |

- |

- |

- |

44-51 |

|

- |

|

Peroxide Number [mval/kg] |

≤10 |

≤10 |

≤10 |

- |

- |

- |

|

- |

|

Water Content [mg /kg] |

- |

- |

- |

- |

- |

- |

≤500 |

- |

|

Gardner Color - |

- |

- |

- |

≤2.5 |

- |

- |

≤1.5 |

- |

|

Typical Data |

|

|

|

|

|

|

|

|

|

Molecular Weight,Mn [g/mol]** |

approx.2,600** |

approx.4,600** |

approx.2,900** |

approx.2,900** |

approx.3,100 |

approx.2,900*** |

approx.3,200*** |

approx.3,000*** |

|

Iodine No. [g lod/100g] |

420-480 |

420-480 |

approx.400 |

380-420 |

350-390 |

420-440 |

- |

- |

|

Density at 20°C [g/cm³] |

0.90-0.92 |

0.90-0.92 |

0.89-0.92 |

approx.0.95 |

approx. 0.96 |

0.90-0.92 |

0.8 -1.0 at 25°C |

- |

|

Gardner Color - |

≤1 |

≤4 |

≤1 |

- |

≤3.0 |

≤1 |

- |

approx.6 |

|

Flash Point [℃] |

approx.180 |

approx.200 |

>245 |

approx.300 |

approx.260 |

approx. 215 |

- |

- |

|

Ignition Temperature [℃] |

approx.360 |

approx.350 |

approx.360 |

approx.360 |

approx.375 |

approx. 375 |

- |

- |

|

Pour Point [℃] |

approx.-55 |

approx.-50 |

approx.-27 |

approx.-25 |

approx.-18 |

approx. -18 |

- |

- |

|

Glass transition Temperature, Tg [℃] |

approx.-102 |

approx.-104 |

approx.-70 |

approx.-95 |

approx.-100 |

approx.-80 |

approx.-80 |

approx.-83 |

|

Mean functionality - |

- |

- |

- |

- |

- |

approx.2.4(-OH) |

approx. 1.5(Silane) |

2.4(Methacrylate) |

|

Residue on Ignition at 950°C [wt.%] |

- |

- |

- |

- |

- |

- |

1.0 -3.5 |

- |

Note: all POLYVEST® grades are supplied in liquid viscous form.

* EP = Experimental Product. The indicated properties are target values and may be subject to change during the upscaling process.

** = Determination via GPC calibrated with polystyrene standard.

*** = Determination via GPC calibrated with polybutadiene standard.

ANALYTICAL METHODS

Viscosity

Determination according to DIN EN ISO 3219.

Acid Number

Determination according to DIN EN ISO 2114.

Hydroxyl Number

Determination according to DIN 53 240-2.

Peroxide Number

Determination according to DGF-method: C-VI-6a (84).

Iodine Number

Determination according to DIN 53 241.

Molecular Weight, Mn

Determination via GPC according to DIN 55 627-1,

calibrated either with polystyrene or polybutadiene standards (please see footnote for details)

Density

Determination according to DIN ISO 2811-1 (at 20°C).

Determination according to DIN 51757, method 4 (at 25°C).

Flash Point

Determination according to DIN EN ISO 2719.

Gardner Color

Determination according to DIN EN ISO 4630.

Ignition Temperature

Determination according to DIN 51 794.

Pour Point

Determination according to DIN ISO 3016.

Glass Transition Temperature, Tg

Determination according to DIN EN ISO 11 357-1.

Water Content

Determination according to DIN 51777-2.

Residue on Ignition at 950°C

Determination according to ASTM D 6740.