VESTOPLAST® - APAO

VESTOPLAST® grades are amorphous poly-alpha-olefins produced with three monomers - ethylene, propylene and butene-1.

It is mainly used as a raw material for hot melt adhesives that are applied within several industries like hygiene, automotive, packaging and woodworking.

All VESTOPLAST® grades are produced to specifi cation in a continuous Ziegler low-pressure polymerization process.

Based on the special process,they have excellent properties,mainly reflected in hardness,cohesion, melt viscosity, crystallinity, crystallization rate and lower density about 0.86g/cm3.

|

Product Range |

|||||||||||

|

Properties |

Melt Viscosity |

Softening Point |

Needle Penetration |

Thermal Stability |

Tensile Strength/ |

Shear Modulus |

Molecular Weight |

Open Time [s] resp. |

Glass Transition |

Density at 23 °C |

Shore Hardness A |

|

(1-)Butene-rich |

|

|

|

|

|

|

|

|

|

|

|

|

308 |

8,000±2,000 |

136±6 |

17±3 |

65-70 |

1.5 / 500 |

14 |

11,300/49,000 |

4 |

-29 |

0.87 |

n.d. |

|

408 |

8,000±2,000 |

118±4 |

5±2 |

85-90 |

6.8 /80 |

70 |

11,600/48,000 |

65 s |

-27 |

0.90 |

94 |

|

508 |

8,000±2,000 |

84±4 |

14±3 |

60-65 |

1.5 /340 |

12 |

11,800/52,000 |

15 |

-31 |

0.87 |

74 |

|

520 |

22,000±4,000 |

87±4 |

14±3 |

65-70 |

2.4/80 |

7 |

13,900/63,000 |

15 |

-29 |

0.88 |

76 |

|

608 |

9,000±3,000 |

157±4 |

18±3 |

60-65 |

1.5 /480 |

11 |

12,300/46,000 |

3 |

-32 |

0.87 |

76 |

|

EP V2103* |

2,500±500 |

103±3 |

12±3 |

90-95 |

2.0/40 |

n.d. |

8,500/50,000 |

-5 |

-33 |

0.86 |

n.d. |

|

EP V2094* |

2,500±500 |

94±4 |

20±4 |

80-85 |

1.0/70 |

n.d. |

9,000/55,000 |

>10 |

-38 |

0.86 |

n.d. |

|

Propene-rich |

|

|

|

|

|

|

|

|

|

|

|

|

703 |

2,700±700 |

124±6 |

12±3 |

75-80 |

2.1/43 |

41 |

7,300/34,000 |

15 s |

-28 |

0.87 |

87 |

|

704 |

3,500±500 |

105±5 |

23±5 |

70-75 |

0.5 /100 |

7.5 |

8,000/35,000 |

80 s |

-36 |

0.87 |

n.d. |

|

708 |

8,000±2,000 |

106±4 |

19±3 |

85-90 |

1.0/330 |

4 |

11,500/75,000 |

55 s |

-33 |

0.87 |

67 |

|

750 |

50,000±10,000 |

107±4 |

14±3 |

85-90 |

5.0 / 1,000 |

14 |

18,100/92,000 |

50 s |

-33 |

0.87 |

75 |

|

751 |

50,000±10,000 |

99±4 |

25±3 |

60-65 |

1.5 / 1,000 |

2 |

18,800/88,000 |

30 |

-33 |

0.87 |

43 |

|

792 |

120,000±30,000 |

108±4 |

14±3 |

90-95 |

5.8 / 1,200 |

7 |

23,800/118,000 |

2 |

-27 |

0.87 |

n.d. |

|

828 |

25,000±7,000 |

161±4 |

22±3 |

95-100 |

1.0/550 |

4 |

13,200/61,000 |

70 s |

-35 |

0.87 |

n.d. |

|

888 |

120,000±40,000 |

161±5 |

16±4 |

115-120 |

2.5 /850 |

6.5 |

15,000/104,000 |

4 s |

-36 |

0.87 |

n.d. |

|

891 |

115,000±35,000 |

162±4 |

22±4 |

105-110 |

2.0 /1,000 |

3 |

18,800/85,000 |

40 s |

-33 |

0.86 |

n.d. |

|

EP 807* |

7,000±2,000 |

161±3 |

7±3 |

125-130 |

4.0/40 |

n.d. |

n.d. |

<2 s |

n.d. |

n.d. |

n.d. |

|

Silane modified |

|

|

|

|

|

|

|

|

|

|

|

|

206 |

5,000±1,000 |

98±4 |

19±3 |

> 1601) |

1.9/720 |

n.d. |

10,600/38,000 |

~20 s |

-28 |

0.87 |

n.d. |

*Experimental Product 1)after curing n.d. = not determined

A special grade for special applications

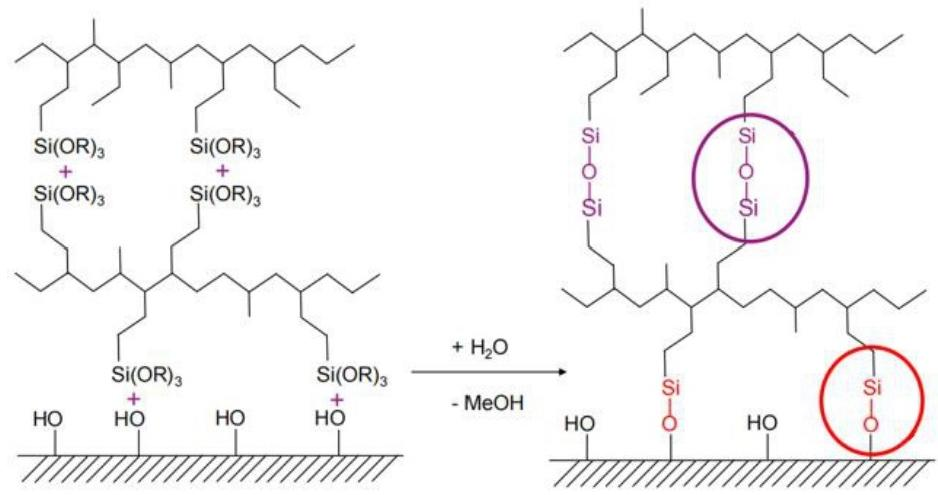

VESTOPLAST® 206 is a reactive adhesive raw material based on a silane grafted polymer which is moisture curing and has a unique amorphous poly-alpha-olefin backbone structure. It is characterized by its excellent adhesion to a very wide range of plastics (e.g. polypropylene, polyester and polyamide), to wood and ‘hard-to-adhere-to’ polar substrates like glass, ceramics and metals.

Product characteristics

Improving cohesion bonding by cross-linking molecular chains

Improving adhesion to the substrate through cross-linking with a surface-active substrate, such as the surface of glass